PRODUCTS

Pads

For those who make safety a top priority for their athletes

Benefits:

Provide better shock absorbency — and protection for players

Create a smoother, more uniform field

Increase lifespan of the turf itself

Allow clients to “tune” fields and add more sand to speed up the surface

Enable us to reduce the height of the turf to increase pile density and reduce the quantities of expensive alternative infills required

Can often be used for more than one field life cycle, making costs over time very attractive

Shock pads are separate elastomeric underlays composed of foam, rubber granules, beads, or fiber blends bonded by strong adhesive. Installed beneath synthetic turf, they cushion impacts and reduce joint stress. While many proven shock pad products have been available for decades, today’s booming turf market has spurred newer technologies and engineered materials to enhance energy absorption and durability. In our laboratory, each pad undergoes rigorous testing—including impact attenuation, compression resistance, and accelerated weathering—ensuring consistent performance across climates. Only pads that meet our strict safety and longevity criteria are approved for athletic fields, playgrounds, and landscaping projects.

GET STARTED HERE:

-

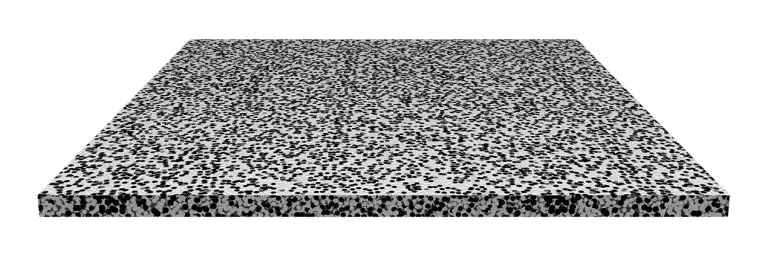

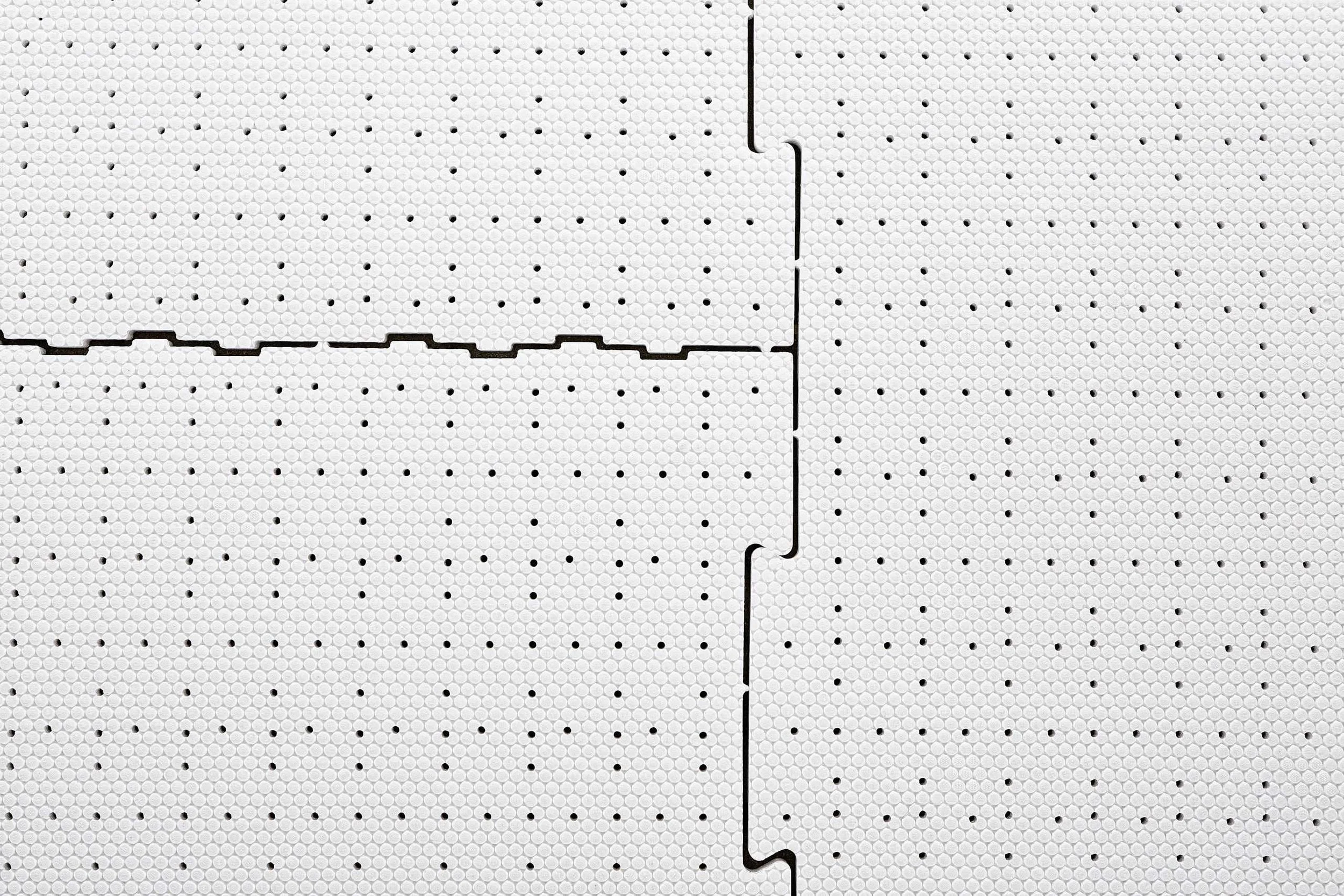

Often simply called “Brock” pads, after the industry leader’s brand, these systems consist of small beads of polypropylene molded under pressure into a certain design. These pads are supplied on pallets and are fitted together on site.

Beaded Polypropylene

-

Generally either cross-linked polyethylene (Trocellan) or PVC nitrile rubber pad formulations (Armacell), these pads are extruded to guarantee uniform thickness and density. Proven for decades for turf applications, foam pads are priced right, can be made in long continuous rolls and can be seamed properly for a monolithic underlayment.

Closed Cell Foams

-

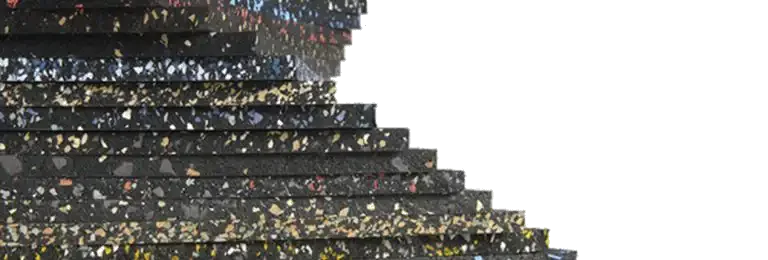

Rubber crumb pads have been proven in use for decades. Heavy, durable and naturally porous, rubber pads are generally used for more than one lifecycle of turf. These pads are offered in two basic formats: Factory Made Pads and Elastic Layers (E-Layer®) Pads.

Rubber Pads

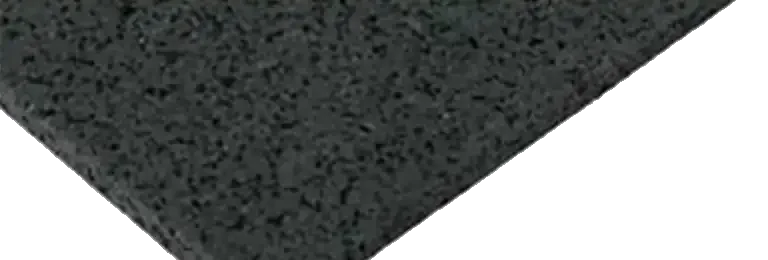

Factory-Made Rubber Pad

-

Factory-Made pads that are either extruded (Enplast and Ecore) or formed into large buns under heat and pressure and then “peeled” into continuous rolls (Regupol). Factory-made pads can incorporate sustainable, recycled Nike Grind materials.

Elastic Layer Rubber Pad

-

Elastic Layer (E-Layer®) pads that are paved-in-place on site using specially modified running track pavers with heated screeds. These pads often have a mix of small stones, foam and rubber granules bound by high grade polyurethane binder.